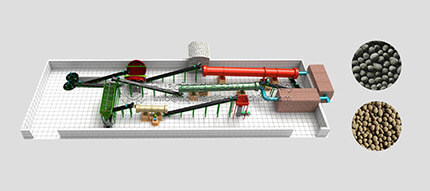

Mixing equipment in NPK fertilizer production process

In NPK production line, blender will be used to mix materials. Here is a brief introduction of screw blender.

Structure of screw mixer

Screw mixer is composed of motor, reducer, bracket, screw, shell and other parts. The shell has a feed port, a discharge port and a body seat. There are two types of reducer: cycloid pin gear and worm gear. The screw stirring bar is designed with double cantilever, unequal length, unequal screw distance and different speed. Different from the rotary drum granulator pelleting. This machine is mainly used for bulk blending fertilizer.

The mixer is designed to rotate asynchronously. The screw rotates around its center line and revolves around the conical center line, so that the materials can be fully mixed. Due to the introduction of advanced technology design and manufacture, so that the mixed materials will not be crushed and crushed, no column angle, deposition and other phenomena. The material size is 20~200 mesh, and the mixing time is 5~8min. The discharge port device is equipped with a manual or electric mechanism. The shell and the parts in contact with the material are suitable to be made of stainless steel. This equipment can also be equipped with a water spray mechanism according to the requirements of the production process.

评论

发表评论