Main installation procedures of equipment in organic fertilizer production line

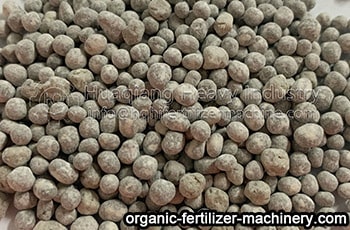

With the development of green agriculture, the demand for organic fertilizer products is increasing. Organic fertilizer production equipment is gradually developing towards large-scale and automated development. In particular, the larger and larger the equipment of the Huaqiang factory, the design structure and manufacturing technology have new improvements, and the requirements for installation technology are also higher. Here Huaqiang Enterprise takes large-scale organic fertilizer complete equipment as an example, to introduce the installation process of organic fertilizer production line to users. Fertilizer pelletizing equipment is the main machinery of the whole organic fertilizer production line project. We designed NPK fertilizer granulator , which adopts double slide shoe bearing. Compared with hollow shaft mill of the same specification, slide shoe bearing mill has the advantages of high strength, stability and high output of mill barrel. In the whole process, it is ve