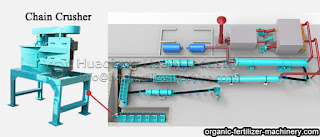

How to choose between chain crusher and half-wet material crusher

In fertilizer production, the applicable scenarios of chain crusher and half -wet material crusher are significantly different. Choosing the right equipment can make production more efficient. Chain crusher is good at processing dry hard raw materials. Faced with low-humidity (water content <15%) block materials such as phosphate rock powder and potassium salt, the impact force generated by the high-speed rotation of its cross manganese steel chain can break 60mm agglomerates into 3-5mm particles, and it is not easy to clog. Its advantage lies in its high crushing hardness, which is suitable for processing mineral raw materials in compound fertilizer production, can ensure the uniformity of material particles, and lay the foundation for subsequent mixing processes. Half -wet material crusher is specially designed for high-humidity raw materials. For materials with a water content of 20%-50% such as fermented chicken manure and cow dung, its double-layer blades and kneading mechani...