Organic fertilizer equipment changes to green ecology

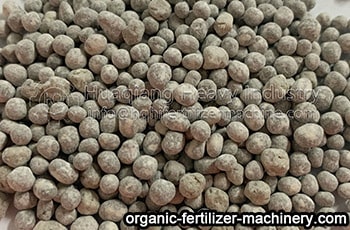

With the improvement of people's quality of life, people put forward higher requirements for agricultural products, non-toxic and pollution-free green food has gradually become a new favorite on the table, which also requires modern agricultural production to change to green ecology. People's demand for high-quality agricultural products promotes the development of organic fertilizer, which provides a great space for the development of organic fertilizer making machine . The development of agricultural production requires the protection of ecological environment and sustainability, which makes organic fertilizer re-enter the field of agricultural production. Organic fertilizer is a kind of fertilizer which is made of chicken manure, pig manure and other animal manure as raw materials through the treatment of organic fertilizer production line equipment and drum granulator . Organic fertilizer retains the original nutrients in chicken manure and pig manure, and eliminates ha...