Classification and description of organic fertilizer granulator

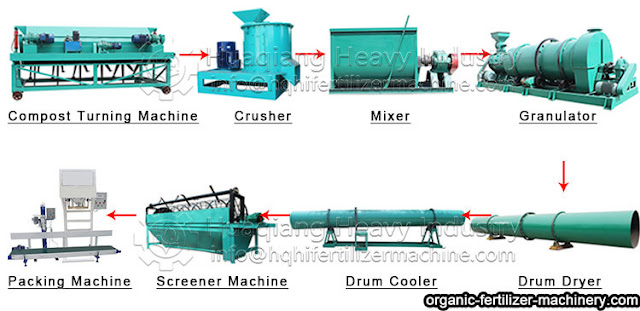

In order to process commercial organic fertilizer with animal manure, the equipment and early fermentation are the key to the production. In the early stage of fermentation, the C / N ratio, moisture and oxygen status of fermentation materials should be adjusted, the working conditions of microorganisms should be improved, and the fermentation time of organic materials should be shortened. In the later stage, the processing of organic fertilizer mainly focused on granulation. Organic fertilizer granulating machine is a kind of molding machine which can make material into specific shape. There are many kinds of granulators, such as rotary drum granulator, new type organic fertilizer granulator , disc granulator, two in one NPK fertilizer granulator, flat die pellet mill, etc. According to the characteristics of production materials and the requirements of granulation, different granulating equipment can be selected. The disc angle of the disc granulator adopts the whole arc structu