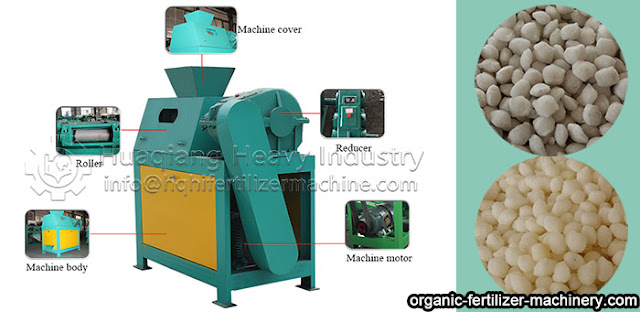

New type fertilizer stirring tooth granulator for processing organic fermentation products

With the diversification of raw materials, organic fertilizer manufacturers are constantly developing new granulation equipment. In the production of ordinary organic fertilizer, there is a stirring tooth fertilizer granulator, which has high production efficiency and good product quality. In terms of organic-inorganic compound fertilizer, there is also a new NPK fertilizer granulator, which is improved on the basis of the agitating gear granulator, which solves the problem of material adhering to the wall and produces beautiful particles. Performance of new type NPK fertilizer granulator (1) With the development of agriculture, the improvement of technology and the diversification of demand, the new NPK fertilizer granulator is a kind of organic fertilizer granulator. The wet granulator of organic fertilizer can realize the material selection. As long as the organic matter after effective fermentation can be granulated by the new granulator, which breaks the limitations and obs